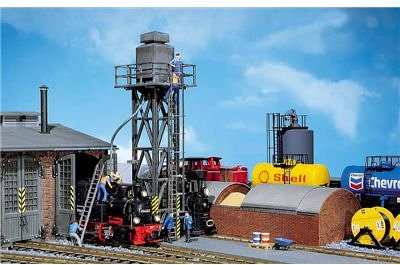

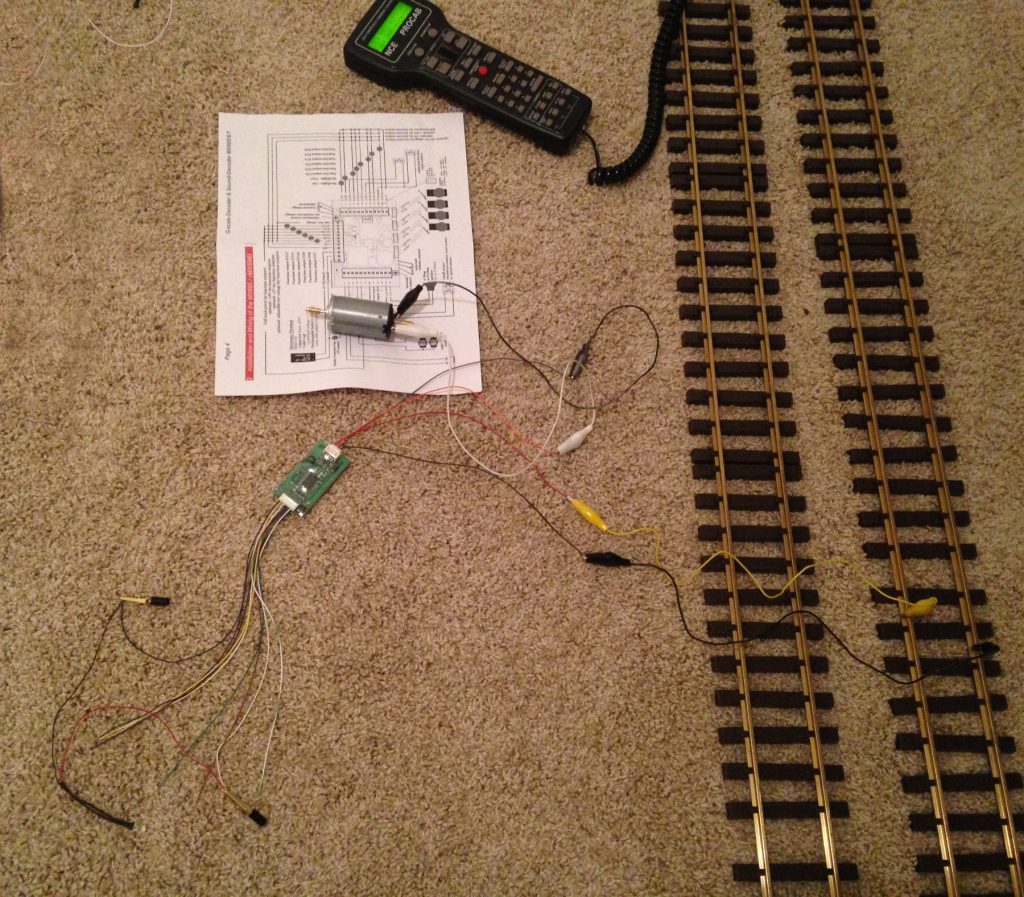

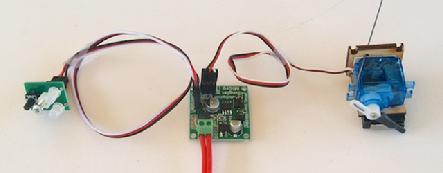

I’ve got my first servo-controlled switch on the layout. I’m using a Tam Valley servo singlet,

which gets both power and DCC signal from the track. The amperage draw is nominal when the decoder is just listening, and since at most I would ever move two of these simultaneously I think it’s ok. My layout is rather on the small side–small enough that I don’t expect to ever run more than two locomotives at a time.